Kombaresarada gaaska Piston (compressors-ka soo noqnoqda) waxay noqdeen qalabka asaasiga ah ee cadaadiska gaaska warshadaha sababtoo ah wax soo saarkooda cadaadiska sarreeya, kontoroolka dabacsan, iyo isku halaynta gaarka ah. Maqaalkani wuxuu si nidaamsan u faahfaahiyay faa'iidooyinkooda farsamo ee xaaladaha cadaadiska gaaska ee noocyada badan, oo ku salaysan mabaadi'da naqshadaynta.

I. Naqshadaynta Qaab dhismeedka Muhiimka ah

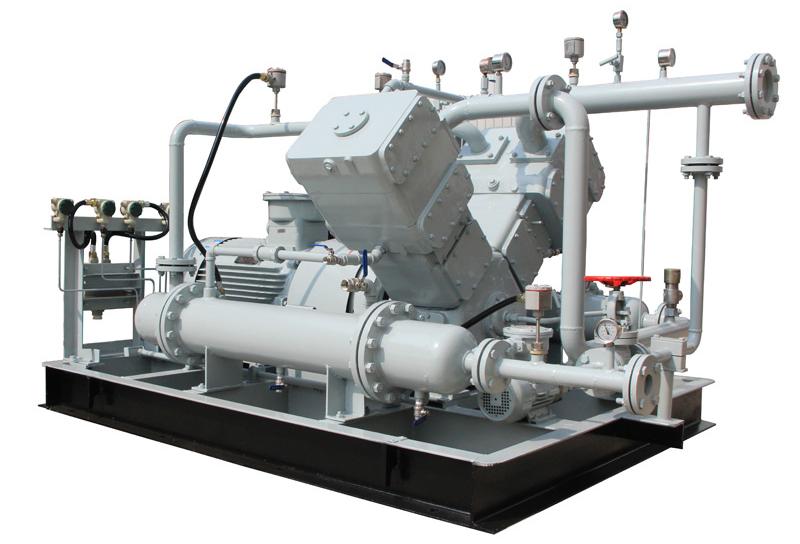

Waxqabadka kombaresarada gaaska piston waxay ka timaadaa nidaam qayb ah oo si sax ah loo agaasimay, oo ay ku jiraan qaybaha muhiimka ah ee soo socda:

1. Isku-xidhka Silinder-Xoogga Sare

Laga sameeyay birta shubka ah, birta daawaha ah, ama alaabta dahaarka khaaska ah si ay ugu adkaysato daxalka wakhtiga dheer ee ka imanaya warbaahinta gardarada ah sida gaaska acidic (tusaale, H₂S) iyo ogsijiinta cadaadiska sare leh.

Kanaalada qaboojinta ee isku dhafan ee biyaha/saliida si si sax ah loo maareeyo isbedbedelka heerkulka ee ka dhasha guryaha gaaska (tusaale, viscosity hoose ee hydrogen, falcelinta sare ee ammonia).

2. Qalab badan oo Piston Assembly

Piston Crown: Xulashada agabka oo loogu talagalay kiimiko gaaska-tusaale, 316L birta aan lahayn ee caabbinta daxalka gaaska ka kooban, dahaarka dhoobada ee jawiga heerkulka sareeyo ee CO₂.

Nidaamka Xiritaanka: Wuxuu adeegsadaa garaafyada, PTFE, ama shaabadadaha isku dhafan birta si looga hortago daadinta gaaska cadaadiska sare leh (tusaale, helium, methane), hubinta hufnaanta cadaadiska ≥92%.

3. Nidaamka Valve Intelligent

Si fir-fircoon u habeeya wakhtiga qaadashada/dhamaysta waalka oo wiish si uu u habeeyo cufnaanta gaasta ee kala duwan iyo saamiga isku xidhka (tusaale, nitrogen at 1.5:1 ilaa hydrogen at 15:1).

Taarikada waalka u adkeysata daalka waxay u adkeystaan baaskiil wadid heersare ah (≥1,200 wareego/daqiiqo), kordhinta mudada dayactirka ee jawiga gaaska guban kara/qarxa.

4. Unugga isku-buuqa ee Modular

Waxay taageertaa isku xidhka 2-ilaa 6-heer dabacsan ee isku xidhka, oo leh cadaadis hal-marxale ah ilaa 40-250 bar, buuxinta baahiyaha kala duwan ee kaydinta gaaska aan shaqayn (tusaale, argon) ilaa cadaadiska syngas (tusaale, CO+H₂).

Isku xirka degdega ah ayaa awood u siinaya habaynta nidaamka qaboojinta degdega ah ee ku salaysan nooca gaaska (tusaale, qaboojinta biyaha ee acetylene, qaboojinta saliidda ee Freon).

II. Faa'iidooyinka ku habboonaanta Gaaska Warshadaha

1. Waafaqid Buuxa oo Warbaahineed

Gaasaska Daxalka: Agabka la wanaajiyey (tusaale, Hastelloy cylinders, bistoonada alloy titanium) iyo adkaynta dusha sare waxay xaqiijiyaan adkeysiga jawiga baaruud- iyo halogen qani ku ah.

Gaasaska Nadiifinta Sare: Saliid la'aanta saliidda iyo shaandhaynta aadka u saxda ah ayaa lagu gaadhay TS ISO 8573-1 Nadaafadda heerka 0 ee nitrogen-ka heerka elektiroonigga ah iyo ogsijiinta caafimaadka.

Gaasaska Ololi kara/Qaraxa: Waafaqsan shahaadooyinka ATEX/IECEx, oo ay ku qalabaysan yihiin xakamaynta dhimbiil iyo dampers-ka cadaadiska cadaadiska ee maaraynta badbaadada leh ee hydrogen, oxygen, CNG, iyo LPG.

2. Awoodaha Hawleed ee La-qabsiga

Xaddiga Socodka Balaadhan: Dareewalada isdabajoogga ah iyo hagaajinta mugga nadiifinta ayaa awood u siinaya xakamaynta socodka tooska ah (30%-100%), oo ku habboon wax soo saarka joogtada ah (tusaale, soo kabashada dhirta kiimikada) iyo sahayda joogtada ah (tusaale, unugyada kala soocida hawada).

Xakamaynta Smart: Dareemayaasha isku dhafan ee isku dhafan ee gaaska si toos ah u hagaajiya cabbirada (tusaale, heerkulbeegyada heerkulbeegyada, heerarka saliidda) si looga hortago cilladaha ay sababaan isbeddellada hantida gaaska degdega ah.

3. Hufnaanta Qiimaha Nolosha

Naqshadaynta Dayactirka Hoose: Nolosha qaybta muhiimka ah ayaa lagu kordhiyey>50% (tusaale, 100,000-saacadood ee dayactirka shafka), yaraynta wakhtiga hoos u dhaca goobaha khatarta ah.

Hagaajinta Tamarta: Qaloocayada isku dhejinta ee ku habboon gaaska adiabatic tusaha (k-qiimaha) waxay gaadhaan 15%-30% kaydka tamarta marka la barbar dhigo moodooyinka caadiga ah. Tusaalooyinka waxaa ka mid ah:

Hawo cadaadis leh: Awood gaar ah ≤5.2 kW/(m³/daqaddii)

Kobcinta gaasta dabiiciga ah: hufnaanta Isothermal ≥75%

III. Codsiyada Warshadaha Muhiimka ah

1. Heerarka Gaasaska Warshadaha (Ogsajiin/Nitrojiin/Argon)

Soo saarista birta birta iyo semiconductor, nashqado bilaa saliid ah oo leh shaandho molecular daawaynta ka dib waxay hubisaa 99.999% nadiifinta codsiyada sida gaashaanka birta dhalaalaysa iyo samaynta wafer.

2. Gaasaska Tamarta (Hydrogen/Syngas)

Cadaadiska marxaladaha badan (ilaa 300 bar) oo ay weheliso nidaamyada xakamaynta qaraxa waxay si badbaado leh u maareeyaan hydrogen iyo carbon monoxide ee kaydinta tamarta iyo isku dhafka kiimikada.

3. Gaasaska dilaaca (CO₂/H₂S)

Xalalka u adkaysta daxalka ee habaysan—tusaale, dahaarka carbide tungsten iyo saliidaha u adkaysta aashitada—waxay wax ka qabtaan sulfur qani, xaaladaha qoyaanka sare ee soo celinta saliida iyo qabashada kaarboonka.

4. Gaasaska Elektarooniga ah ee Gaarka ah (Fluorinated Compounds)

Dhismaha daboolka buuxa iyo helium mass-spectrometer ogaanshaha daadinta (heerka daadinta <1×10⁻⁶ Pa·m³/s) waxay hubisaa in si badbaado leh loo maaraynayo gaasaska halista ah sida tungsten hexafluoride (WF₆) iyo nitrogen trifluoride (NF₃) ee warshadaha sawirkavoltaic iyo IC.

IV. Horumarka Tignoolajiyada Cusub

Nidaamyada mataanaha dhijitaalka ah: qaabaynta xogta-waqtiga-dhabta ah waxay saadaalisaa xidhashada giraanta piston-ka iyo cilladaha waalka, taas oo awood u siinaysa digniinaha dayactirka 3-6 bilood ka hor.

Isku dhafka Geedi socodka Cagaaran: Unugyada soo kabashada kulaylka qashinka waxay 70% kulaylka cadaadisku u beddelaan uumi ama koronto, iyagoo taageeraya yoolalka dhexdhexaadnimada kaarboonka.

Horumarka Cadaadis-sare ee aadka u sarreeya: Tignoolajiyada cilinder-ka ee hore loo adkeeyay waxay ku guulaysataa isku-buufin hal-mar ah> 600 bar ee goobaha shaybaadhka, taasoo u gogol xaaraysa kaydinta hydrogen iyo gaadiidka mustaqbalka.

Gabagabo

Compressors gaaska Piston, oo wata qaabdhismeedkooda modular iyo awoodaha is-beddelka, waxay keenaan xalal lagu kalsoonaan karo oo loogu talagalay farsamaynta gaaska warshadaha. Laga soo bilaabo isku-buufinta joogtada ah ilaa xakamaynta gaaska khaaska ah ee xaalada-aadka u daran, hagaajinta qaab-dhismeedku waxay xaqiijisaa badbaado, hufan, iyo hawlgallo kharash-ool ah.

Tilmaamaha xulashada kombaresarada ama warbixinnada xaqiijinta farsamada ee ku habboon warbaahinta gaaska gaarka ah, fadlan la xiriir kooxdayada injineernimada.

Qoraallada Farsamada:

Xogta laga soo qaatay ISO 1217, API 618, iyo heerarka kale ee imtixaannada caalamiga ah.

Waxqabadka dhabta ahi wax yar wuu kala duwanaan karaa iyadoo ku xidhan halabuurka gaaska iyo xaaladaha deegaanka.

Habaynta qalabku waa inay u hoggaansamaan xeerarka badbaadada ee qalabka gaarka ah.

Waqtiga boostada: Meey-10-2025