Cadaadiska Sare ee Nadiifinta Sare ee Warshadaha Ogsajiinta Helium Diaphragm Compressor

Xuzhou Huayan Gas Equipment Co., Ltd.waa bixiye caalami ah oo heersare ah oo bixiya xalalka cadaadiska gaaska. Iyada oo khibrad la ururiyey ee naqshadaynta iyo wax soo saarka tobanaan sano, shirkadeena waxay haysataa awoodo wax soo saar oo dhamaystiran oo ka kooban been-abuur xirfadeed, shubid, daawaynta kulaylka, alxanka, mashiinada saxda ah, tijaabinta shirarka, iyo hababka xaqiijinta tayada. Iyaga oo ay taageerayaan koox farsamo oo u go'an oo ka kooban 120 xirfadlayaal iyo xarun wax soo saar oo baaxad leh oo dhan 90,000 m², waxaanu ilaalinaynaa qalabka tijaabada farsamada sare iyo hababka xakamaynta tayada adag si loo hubiyo waxqabadka badeecada sare.

Awood u leh naqshadaynta, soo saarista, iyo rakibidda qalabka iyadoo loo eegayo xuduudaha macaamiisha gaarka ah, waxaan hadda gaadhnay awoodda wax-soo-saarka sanadlaha ah ee 500 unugyada kombaresarada gaaska. Wanaagsanaanteena farsamo waxay awood u siineysaa horumarinta kombaresarada oo leh cadaadis dheecaan ah ilaa 100MPa, oo buuxinaya shuruudaha warshadaha ugu baahida badan.

Iyada oo leh raad caalami ah oo ku fidsan in ka badan 50 waddan oo ku kala baahsan shanta qaaradood, oo ay ku jiraan suuqyada muhiimka ah sida Indonesia, Egypt, Vietnam, South Korea, Thailand, Finland, Australia, Czech Republic, Ukraine, iyo Russia, waxaan u soo bandhignaa xalal toosan oo dhamaystiran macaamiisha adduunka oo dhan. Ballanqaadkayaga ku aaddan heerka ugu sarreeya ee hawlgalku wuxuu hubinayaa in macaamiil kastaa helo qalab wax-qabad sare leh oo ay ku lammaan yihiin taageero farsamo oo xirfad leh iyo adeeg jawaab celin ah.

mitir laba jibbaaran

Kooxda Farsamada

Khibrad wax-soo-saarka

WADAMADA Dhoofinta

A kombaresarada diaphragmwaa barokac khaas ah oo togan oo caan ku ah kartida uu u leeyahay in uu xakameeyo gaaska leh daahir gaar ah, xasaasi ah, ama khatar iyada oo aan wasakhayn ama dareerin. Si ka duwan kombaresarada piston-ka dhaqameed, waxay isticmaashaa diaphragm dabacsan oo biyo leh si ay uga soocdo gaaska cufan ee kiishka saliidaysan iyo bistoonka.

Astaamaha Muhiimka ah:

1,Xiritaanka Hermetic: Birta ama elastomer diaphragm waxay abuurtaa xayndaab dhammaystiran, oo aan lahayn dareere u dhexeeya gaaska iyo dareeraha haydarooliga / saliidaha. Tani waa sifadeeda qeexan.

2,Wax wasakhaysan eber: Waxa ay dammaanad qaadaysaa in gaaska la isku cadeeyey uu ahaado mid aan saliid lahayn oo aan wasakhayn saliidaha ama xidho qaybo ka mid ah habka wadista. Muhiim u ah codsiyada daahirsanaanta sare.

3,Kahortagga daadinta: Waxay si dhab ah u baabi'isaa qiiqa baxsadka ah, taas oo ka dhigaysa mid muhiim u ah la tacaalida sunta, ololka, qaraxyada, ama gaaska waxyeelada leh ee deegaanka.

4,Awoodda Cadaadiska SareAwood u leh in lagu gaaro cadaadiska dareeraha aadka u sarreeya (badanaa ilaa 3000 bar / 43,500 psi iyo wixii ka dambeeya), gaar ahaan qaabeynta marxaladaha badan.

5,Qabashada Gaaska Kala DuwanKu haboon in la cadaadiyo gaas badan oo kala duwan, oo ay ku jiraan aadka u falcelisa, daxalka, aadka u saafiga ah, qaali ah, ama noocyada khatarta ah ee waxyeelayn kara ama ay wasakhayn karaan naqshadaha kale ee kombaresarada.

6,Heerarka socodka dhexdhexaadka ahSida caadiga ah waxaa loogu talagalay heerarka socodka hooseeya ama dhexdhexaadka ah marka loo eego kombaresarada waaweyn ee isdhaafsiga ama centrifugal.

Gaasas ku habboon

Gaasas ku habboon

1. Nolol adeeg oo dheer

Qalabka madaxa dhululubada ee kombaresarada diaphragm waa la been abuuraa oo la farsameeyaa, ka dib daaweynta kulaylka, maaddadu waxay leedahay iska caabin cadaadis sare ah, kordhinta nolosha adeegga qalabka ugu yaraan 20 sano.

2. Iska caabin daxalka

Dhuumaha kombaresarada diaphragm-ku waxay ka samaysan tahay SS304 ama SS316L birta, taas oo kor u qaadaysa iska caabbinta daxalka ee qalabka ee jawiga qoyan iyo acidic ah, iyada oo aan wax miridh ah lahayn, oo leh muuqaal wanaagsan.

3. Cadaadiska hawada sare

Cadaadiska qiiqa kombaresarka diaphragm wuxuu gaari karaa 90MPa.

4. Nolosha adeegga ee qaybaha nugul

Compressors-ka biyaha qaboojiyay, waxaa jira 5 godad kanaalka biyaha ee madaxa dhululubada. Marka lagu daro qaboojiyaha dibadda ee hoos u dhigaya heerkulka gaaska, waxaanu qaboojinnay madaxa dhululubada si loo yareeyo gaaska oo aan u kordhiyo nolosha adeegga diaphragm iyo valve. Celceliska nolosha adeegga diaphragm-ka waxay gaari kartaa in ka badan 5000h.

5. Waxqabadka shaabadeynta wanaagsan

Madaxa dhululubada asal ahaan waxaa loogu talagalay in lagu rakibo labajibbaaran O-ring, iyo saamaynta xidhiddu aad ayay uga sarraysaa madaxa xuubka furan.

1,Kiimikada Batroolka & Habaynta KiimikadaCadaadiska dhexdhexaadiyeyaasha aadka u daxalka leh, falcelinta sunta ah (tusaale, wax soo saarka PVC ee leh Cl₂), gaaska dib u soo kicinta, cadaadiska hydrogen ee hydrocrackers/hydrotreaters halka ay daahirnimadu muhiim tahay.

2,Saliidda & Gaaska: Cadaadiska gaaska subsea, cirbadeynta gaaska (soo kabashada saliidda oo la xoojiyay), cadaadiska hydrogen ee warshadaha.

3,Samaynta Semiconductor: Waxay lama huraan u tahay bixinta nadaafadda aadka u saraysa (UHP) iyo gaasasyada khaaska ah ee khatarta ah (sida AsH₃, PH₃, SiH₄) agabka wax-soo-saarka iyada oo aan wasakhayn.

4,Falanqaynta & ShaybaarkaBixinta saafiga ah, gaasas-xameeya wasakh-la'aan ah, gaasas cabbiraadda, iyo gaaska muunada ee qalabka sida GC-MS.

5,Hawada & TijaabadaQalabka gaaska cadaadiska sare leh (He, N₂) ee tijaabinta qaybaha gantaallada, nidaamyada cadaadiska, tunnelyada dabaysha.

6,Caafimaadka & DaawooyinkaSoo saarista iyo dhalooyinka gaasas caafimaad oo saafi ah oo sarreeya (O₂, N₂O), hawada nadiifka ah ee hababka.

7,Warshadaha NukliyeerkaXakamaynta qaboojiyeyaasha helium ama gaaska daboolaya.

8,Tamarta & Hydrogen: Cadaadiska hydrogen ee unugyada shidaalka, saldhigyada shidaalka hydrogen (HRS), iyo cilmi-baarista wax-soo-saarka haydaroojin/kaydinta.

9,Tignoolajiyada DeegaankaCadaadiska CO₂ la qabtay ee kala soocida ama ka faa'iidaysiga (CCUS).

| Qaabka | Isticmaalka biyaha qaboojinta (t/saac) | Barokaca (Nm³/saacaddii) | Cadaadiska qaadashada (MPa) | Cadaadiska daalka (MPa) | Cabbirrada L×W×H(mm) | Miisaanka (t) | Awoodda Baabuurka (kW) | |

| 1 | GL-10/160 | 1 | 10 | 16 | 2200×1200×1300 | 1.6 | 7.5 | |

| 2 | GL-25/15 | 1 | 25 | 1.5 | 2200×1200×1300 | 1.6 | 7.5 | |

| 3 | GL-20/12-160 | 1 | 20 | 1.2 | 16 | 2200×1200×1300 | 1.6 | 7.5 |

| 4 | GL-70/5-35 | 1.5 | 70 | 0.5 | 3.5 | 2000×1000×1200 | 1.6 | 15 |

| 5 | GL-20/10-150 | 1.5 | 20 | 1.0 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 6 | GL-25/5-150 | 1.5 | 25 | 0.5 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 7 | GL-45/5-150 | 2 | 45 | 0.5 | 15 | 2600×1300×1300 | 1.9 | 18.5 |

| 8 | GL-30/10-150 | 1.5 | 30 | 1.0 | 15 | 2300×1300×1300 | 1.7 | 11 |

| 9 | GL-30/5-160 | 2 | 30 | 0.5 | 16 | 2800×1300×1200 | 2.0 | 18.5 |

| 10 | GL-80/0.05-4 | 4.5 | 80 | 0.005 | 0.4 | 3500×1600×2100 | 4.5 | 37 |

| 11 | GL-110/5-25 | 1.4 | 110 | 0.5 | 2.5 | 2800×1800×2000 | 3.6 | 22 |

| 12 | GL-150/0.3-5 | 1.1 | 150 | 0.03 | 0.5 | 3230×1770×2200 | 4.2 | 18.5 |

| 13 | GL-110/10-200 | 2.1 | 110 | 1 | 20 | 2900×2000×1700 | 4 | 30 |

| 14 | GL-170/2.5-18 | 1.6 | 170 | 0.25 | 1.8 | 2900×2000×1700 | 4 | 22 |

| 15 | GL-400/20-50 | 2.2 | 400 | 2.0 | 5.0 | 4000×2500×2200 | 4.5 | 30 |

| 16 | GL-40/100 | 3.0 | 40 | 0.0 | 10 | 3700×1750×2000 | 3.8 | 30 |

| 17 | GL-900/300-500 | 3.0 | 900 | 30 | 50 | 3500×2350×2300 | 3.5 | 55 |

| 18 | GL-100/3-200 | 3.5 | 100 | 0.3 | 20 | 3700×1750×2150 | 5.2 | 55 |

| 19 | GL-48/140 | 3.0 | 48 | 0.0 | 14 | 3800×1750×2100 | 5.7 | 37 |

| 20 | GL-200/6-60 | 3.0 | 200 | 0.6 | 6.0 | 3800×1750×2100 | 5.0 | 45 |

| 21 | GL-140/6-200 | 5.0 | 140 | 0.6 | 20.0 | 3500×1380×2350 | 4.5 | 55 |

| 22 | GL-900/10-15 | 2.5 | 900 | 1.0 | 1.5 | 3670×2100×2300 | 6.5 | 37 |

| 23 | GL-770/6-20 | 4.5 | 770 | 0.6 | 2.0 | 4200×2100×2400 | 7.6 | 55 |

| 24 | GL-90/4-220 | 6.0 | 90 | 0.4 | 22.0 | 3500×2100×2400 | 7.0 | 45 |

| 25 | GL-1900/21-30 | 3.8 | 1800 | 2.1 | 3.0 | 3700×2000×2400 | 7.0 | 55 |

| 26 | GL-300/20-200 | 4.2 | 300 | 2.0 | 20.0 | 3670×2100×2300 | 6.5 | 45 |

| 27 | GL-200/15-200 | 4.0 | 200 | 1.5 | 20.0 | 3500×2100×2300 | 6.0 | 45 |

| 28 | GL-330/8-30 | 5.0 | 330 | 0.8 | 3.0 | 3570×1600×2200 | 4.0 | 45 |

| 29 | GL-150/6-200 | 5.0 | 150 | 0.6 | 20.0 | 3500×1600×2100 | 3.8 | 55 |

| 30 | GL-300/6-25 | 4.5 | 300 | 0.6 | 2.5 | 3450×1600×2100 | 4.0 | 45 |

Waxaan haynaa shahaadooyin caalami ah oo la aqoonsan yahay oo ay ku jiraanCEiyoISOheerarka (waxaa aqoonsadayIAF), sidoo kaleECMaqoonsiga u hoggaansanaanta. Shahaadooyinkani waxay muujinayaan sida ay uga go'an tahay tayada, badbaadada, iyo mas'uuliyadda deegaanka:

- Calaamadeynta CEwaxay hubisaa u hoggaansanaanta badbaadada EU, caafimaadka, iyo xeerarka deegaanka, iyagoo dammaanad qaadaya gelitaanka suuqa xorta ah ee Yurub oo dhan.

- Shahaadada ISO(oo ay taageerto aqoonsiga IAF) waxay ansixisay u hoggaansanaantayada nidaamyada maaraynta tayada cabbirka caalamiga ah, kor u qaadista joogtaynta hawlgalka iyo kalsoonida macaamiisha.

- Aqoonsiga ECMwaxay hoosta ka xariiqday la jaanqaadkayaga heerarka farsamada iyo waxqabadka warshadaha gaarka ah.

Haddii suuqaagu ama mashruucaagu u baahan yahay shahaado dheeraad ah (tusaale,API,ASME, ama oggolaanshaha gaarka ah ee gobolka), kooxdayada khibradda leh ee farsamada iyo u hoggaansanaanta ayaa kula kaashan doona si hufan si loo helo shahaadooyinka lagama maarmaanka ah. Waxaanu habaynaynaa hanaankeena si aanu u buuxino shuruudahaaga sharci, anagoo hubinayna soo gelida suuqa ee qalabkeena.

Our90,000+ mitir laba jibaaranwax soo saarka casriga ah, oo ay ka shaqeeyaan120+xirfadlayaal, waxay soo bandhigaan xalal injineernimo oo la habeeyey oo leh karti wax-soo-saar sax ah. Ku qalabaysan 20 xarumood oo mashiineed oo CNC ah oo horumarsan, waxaanu qabanaa qalabka shaqada ilaa1200mmdhexroor leh saxnaanta heerka-yar (micron)0.01mm). Nidaamyada xakamaynta tayada adag waxaa ka mid ah hubinta buuxda ee qaybaha muhiimka ah iyadoo la adeegsanayo CMM (Coordinate Measuring Machines) iyo tijaabinta culeyska wejiyada badan ee injineerada shahaadeysan ee shirka kadib. Cutub kastaa wuxuu maraa ansaxinta waxqabadka si uu ugu hoggaansamo heerarka ASME/API iyo qeexida macmiilka, oo ay taageertoISO 9001-shahaadadmaaraynta tayada raadraaca, gaarsiinta la isku halayn karo.

Waxaan isticmaalnaaqiiq la'aanqaababka alwaax adagshahaado ka dhoofinta caalamiga ah ISOheerarka karantiilka. Gudaha gudaha waxaa lagu xoojiyay birta kanaalka si loogu taageero saddex-cabbir, bannaanka waxaa lagu duuduubay 0.8mm ilaalo gees bir ah oo dhumucsan waxaana lagu ilaaliyaa kala-goysyada iyadoo la adeegsanayoXarkaha birta galvanized aan biyuhu lahayn. Naqshadani waxay hubisaa iska caabinta saamaynta, adkaysiga-cadaynta, ilaalinta qoyaanka, iyo ka-hortagga miridhku inta lagu jiro safarka, dammaanad qaadista alaabtaadu si badbaado leh.

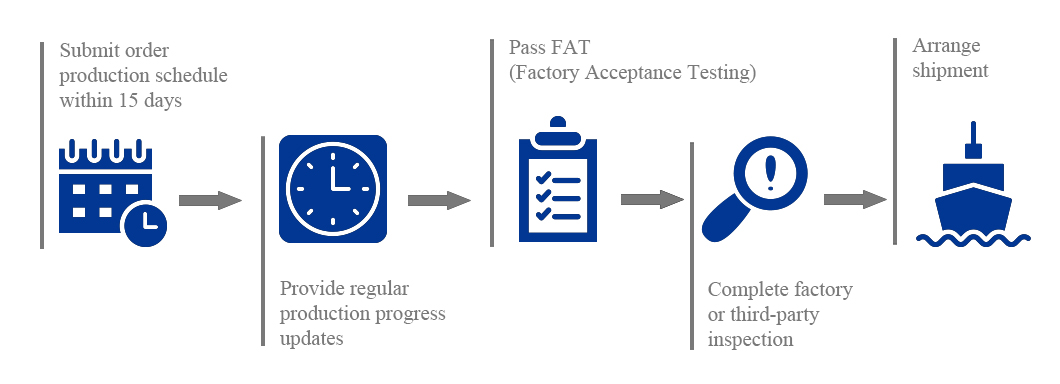

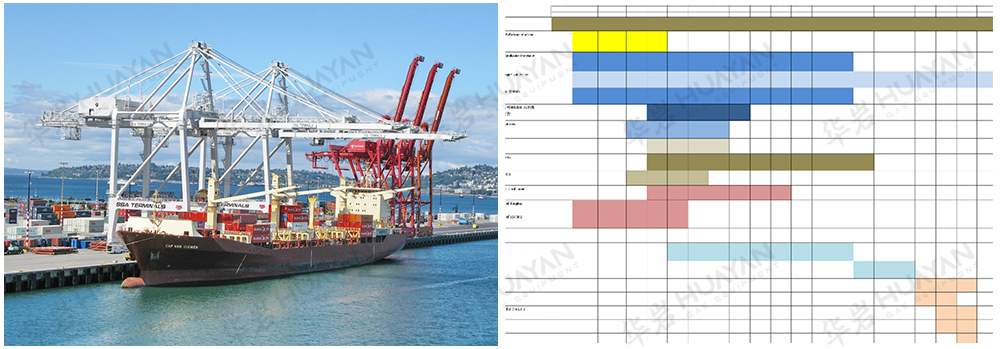

Shirkaddayadu waxay horumarin doontaa jadwallada gaarsiinta habaysan ee mashruucaaga, oo ay taageerayaan xalalka saadka ee isku dhafan ee daboolayagaadiidka cirka, badda, iyo dhulka.

Ka faa'iidaysiga shabakadda gudaha ee Shiinaha iyo iskaashiga caalamiga ah, waxaan hubineynaa hawlgallada hufan ee xudduudaha isaga gudba oo leh raadraaca waqtiga-dhabta ah, taageerada fasaxa kastamka, iyo awoodaha kaydinta ee isku xidhan. Dabacsanaanta hab-dhaqanka badan waxay dammaanad qaadaysaa kharash-ku-ool ah iyo keenista waqtiga loogu talagalay dhammaan noocyada xamuulka.

1.Sidee loo helaa oraah degdeg ah ee kombaresarka gaaska?

1) Heerka socodka/Awoodda socodka: ____ Nm3/saacaddii

2) Nuugista/ Cadaadiska Gudaha: ____ Bar

3) Cadaadiska Bixinta/Wararka:____ Bar

4) Dhexdhexaadka gaaska :____

5) Voltage iyo Joogtada: ____ V/PH/HZ

2.Intee in le'eg ayay tahay wakhtiga dhalmada?

Waqtiga keenista waa ku dhawaad 30-90 maalmood.

3.What ku saabsan danab alaabta? Ma la beddeli karaa?

Haa, danabku waa la beddeli karaa iyadoo loo eegayo weydiintaada.

4.Ma aqbali kartaa amarrada OEM?

Haa, dalabaadka OEM si weyn ayaa loo soo dhaweynayaa.

5.Ma bixin doontaa qayb ka mid ah qaybaha firaaqada ee mishiinnada?

Haa

Rakibaadda iyo hawlgelinta

U dir shaqaale xirfad leh oo goobta jooga si loo hubiyo rakibidda iyo hawlgalka qalabka la bixiyay.

Isticmaal tababar

Rakibado bilaash ah iyo hagitaan shaqo, adeegyo farsamo oo bilaash ah, iyo tababar bilaash ah oo loogu talagalay shaqaalaha.

Booqashooyinka dabagalka joogtada ah

Si joogto ah u samee booqashooyinka dabagalka goobta oo si degdeg ah u bixi adeegyada la socodka alaabta.

Adeegga farsamada

Bixi adeegyo farsamo oo bilaash ah oo looga baahan yahay mashruuca dayactirka.

7 Qof

Kooxda adeegga iibka ka dib xirfadlayaasha.

100% heerka gudbinta

Gaadhi 100% heerka ka gudubka tayada leh ee laga bilaabo soo saarista iyo habaynta ilaa maamulka alaab-qeybiyaha.